-

-

3D Printing Service

3D Printing Service-

3D printing is a process in which materials is jetted or solidified under computer control, with computer software to create a three-dimensional object. 3D printer jets resin according to established model, and solidify it by laser layer by layer, to achieve the final part.

-

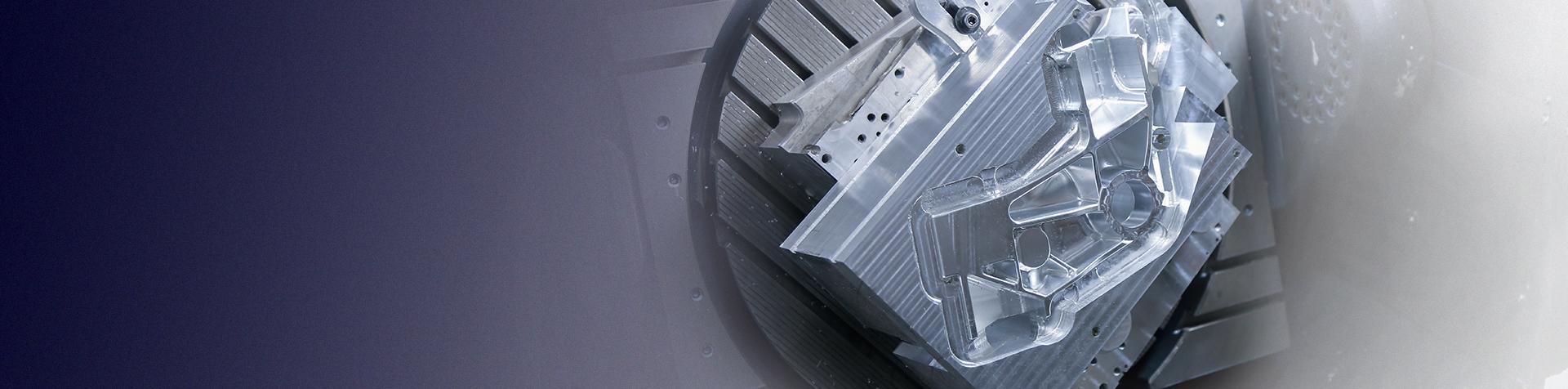

CNC Rapid Prototype

CNC Rapid Prototype-

CNC Rapid Prototypes is a kind of forming method that are suitable for high precision prototyping. Powered by 60 five-axis, four-axis and three-axis CNC Machining Center, HK Tenlita Technology Limited can provide our customers with CNC Machining Service.

-

Vacuum Casting Service

Vacuum Casting Service-

Vacuum casting is used to produce silicone molds from the original sample under a vacuum state and uses PU material to perform deaeration, stirring, pre-heating, injection molding and other processes.

-

Reaction Injection Moulding

Reaction Injection Moulding-

Reaction Injection Moulding (RIM) is the most advanced process for polyurethane parts moulding. Compared with Vacuum Casting Service, moulds are made by harder materials in RIM, which can replicates 200-1000 identical plastic products.

About Tenlita Model

Tenlita Precision Technology is an enterprise with a specialization in the production of CNC models and silicone mold rapid manufacturing. We are a comprehensive company offering services including product design, verification of prototypes, rapid mold production, and small batch manufacturing. We primarily deliver SLS, SLA, vacuum casting, CNC machining, metal and plastic parts processing, reaction injection molding small batch production, and various surface treatments.

HK Tenlita Technology Limited

- Add.:

Hesheng Industry Park, Jienan Road, Humen Town, Dongguan City, Guangdong Province - Mobile:

+86-13530035820

- Email:

lin@tenlita.com

gladycelin@163.com - Social Account:

Skype: lin@tenlita.com

WhatsApp: +86-13530035820